Fuel storage tank maintenance and the benefits of double-skin lining

Published: 13 June 2024

In today’s fuel dependent world, storage tanks are critical components in various industries, ensuring the safe and efficient storage of fuel is critical. Proper maintenance of these tanks is essential to prevent leaks, contamination, and potential environmental hazards. We've delved into the best maintenance practices, the importance of adopting a proactive regime, and the innovative solution of double-skin lining for tanks that have experienced containment breaches and possible subsequent pollution events.

Importance of regular maintenance

Regular maintenance of fuel storage tanks is crucial for several reasons:

- It ensures safety by preventing leaks and spills that could lead to fire hazards and environmental contamination.

- Maintenance enhances efficiency by ensuring that the tanks operate at optimal capacity without interruptions to your operations.

- It extends the lifespan of the tanks by preventing corrosion and other forms of degradation.

- Maintaining tanks in good condition ensures compliance with legal regulations, helping to avoid hefty penalties.

Penalties for leaks and non-compliance

Failing to properly maintain fuel storage tanks and prevent leaks can lead to severe penalties. These penalties are enforced to ensure that companies adhere to environmental regulations and protect public health and safety.

Companies can face substantial fines for environmental violations, with the amount depending on the severity of the leak and the resulting damage. In cases of significant environmental harm, legal action can be taken against the company, resulting in larger financial penalties and damage to the company’s reputation. Additionally, companies are responsible for the costs associated with cleaning up any spills or leaks, which can be significant, especially if groundwater or soil contamination occurs. Regulatory authorities also have the power to shut down operations until compliance is achieved, leading to potential loss of business and revenue.

Key maintenance practices

A good maintenance regime for fuel storage tanks involves several critical steps. Regular inspections are essential for detecting early signs of wear and tear, corrosion, and other potential issues. These inspections should cover both the external and internal parts of the tanks. Periodic cleaning is also vital to remove sludge, debris, and microbial growth that can cause contamination and blockages. This task should be performed by professionals to ensure it is done safely and effectively.

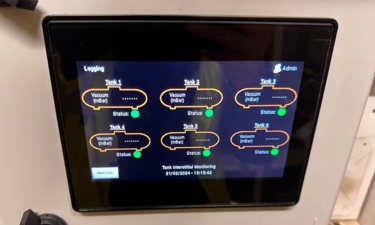

Routine testing is an essential aspect of maintenance. This includes structural integrity and tightness testing, such as pressure tests and non-destructive methods like ultrasonic thickness testing. Continuous monitoring using sensors and monitoring systems can help track the condition of the tank and the fuel it stores in real-time, allowing for early detection of anomalies. Additionally, applying protective coatings and linings can prevent corrosion, significantly extending the life of the tanks.

Double-skin lining: A solution for containment breaches

When a containment breach occurs, it’s essential to address the issue promptly to prevent environmental damage and ensure the continued safe operation of the tank. One effective solution for tanks installed underground is the application of double-skin lining.

Double-skin lining involves adding an additional protective layer inside the tank, creating a secondary containment system that prevents leaks and provides an extra level of security. This method enhances protection by serving as a fail-safe, preventing leaks even if the primary tank wall is compromised. It is a cost-effective alternative to replacing the entire tank, as it minimises downtime and reduces expenses. By protecting the tank from further corrosion and damage, double-skin lining can significantly extend its operational life.

The process of applying double-skin lining starts with an assessment to evaluate the condition of the tank and determine the extent of the breach. Once deemed suitable for double-skin lining, the tank surface is thoroughly cleaned and prepared to ensure proper adhesion of the lining. The lining material, typically a high-performance coating, is then applied meticulously to ensure full coverage and effectiveness. After the lining is applied, it is allowed to cure before a thorough inspection is conducted to ensure it meets the required standards.

Double-skin lining systems that are tested and certified by TÜV to BS EN 13160-7 provide peace of mind for you and your site. This high level testing process ensures only the very robust and technically sound systems are approved and ensure your tanks have protection in the event of a leak.

Best practices for compliance

To avoid penalties and ensure safe operations, companies should adopt several best practices. Staying updated with local, national, and international regulations concerning fuel storage and environmental protection is crucial. Establishing and adhering to a strict maintenance schedule that includes regular inspections, cleaning, and testing is also important. Investment in modern monitoring and inspection technologies, like a TÜV-certified system for your tanks, can help companies stay ahead of potential issues. Ensuring that all personnel involved in the maintenance and operation of fuel storage tanks are properly trained and aware of best practices and regulatory requirements is essential. Finally, developing and maintaining an emergency response plan to address potential leaks or spills quickly and effectively is critical.

Environmental stewardship

Proper maintenance of fuel storage tanks is not just a regulatory requirement but a critical aspect of operational safety and environmental stewardship. By adopting a comprehensive maintenance regime, investing in protective measures like double-skin lining, and staying compliant with regulations, companies can ensure the longevity and safety of their fuel storage systems. The consequences of neglecting these responsibilities can be severe, both financially and environmentally. Therefore, proactive maintenance and adherence to best practices are essential for any business involved in the storage of fuel.

For more information on our TÜV-certified double-skin lining and its benefits, discover more here.

More from our Knowledge Hub

Insights

InsightsEarth Day 2025: Enabling a sustainable future while supporting today’s infrastructure in an evolving energy landscape

Insights

InsightsMitigating climate change risks through planned preventive maintenance

Insights

InsightsProtective coatings: Safeguarding infrastructure against climate change

Insights

InsightsDelivering the Water (Special Measures) Act: Supporting compliance and innovation

Environmental compliance today, creating a sustainable tomorrow

Helping you reduce risk to the environment and your operation by managing assets compliantly while achieving commercial, ESG, and net-zero goals.

Contact our experts