Wavin Compact Pipe®

Ready to discuss your project?

Please leave your details and a member of our team will reach out to discuss your requirements in more detail and arrange next steps.

Wavin Compact Pipe® is designed for use in existing pressure and gravity pipelines for the renewal of drinking water, gas, and wastewater pipelines made of steel, cast iron, or concrete.

It is installed close-fit into an existing pipeline, providing a new structural pipe with a lifetime of 80-100 years.

The tight-fitting Wavin Compact Pipe® acts as a fully independent pressure pipe, ensuring structural integrity even in damaged or cracked host pipes.

Once installation is completed, the Wavin Compact Pipe® will have the same qualities as standard polyethylene pipes.

Visit Group company Public Sewer Services to learn more.

Features

- Uses PE100, a high-grade polyethylene with excellent mechanical and chemical resistance properties

- Highly abrasion-resistant, so is ideal for rising mains

- Installation in continuous lengths ranges from 93 m [DN 500] up to 600 m [DN 150] from a single coil

- Can cope with all bends up to 22.5 degrees

- Suitable for various pipeline materials (steel, cast iron, concrete)

- Can handle high-pressure applications up to 16 bar (water) and 10 bar (gas)

Benefits

Cheaper

Double the life and half the cost, Wavin Compact Pipe® is the cheapest solution on the market at 40% less than open trench technology.

Longer lasting

Wavin Compact Pipe® is a polyethylene liner with a lifetime of 80-100 years. It has exceptional strength and longevity, outperforming many other rehabilitation methods.

Ease of install

Trenchless technology means minimal surface disruption and shorter installation times, suitable for various pipeline materials (steel, cast iron, concrete).

Maintainable

Wavin Compact Pipe® can be connected to, repaired,and cut into again, making it repairable and maintainable by in-house teams.

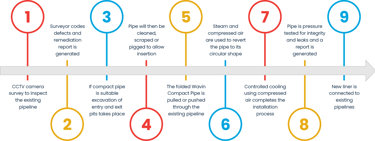

Installation process

Capability

Public Sewer Services follows the installation process directives in DVGW GW320/11.

Public Sewer Services owns all the relevant installation equipment, including:

- Steam unit with integrated process control

- Drum trailer

- Winch and winch tree

- Data storage unit

- Water/steam separator

- Butt-fusion equipment

- Pulling heads

- Expander

- Various standard tools and equipment (incl. a compressor) and auxiliary devices

You might also be interested in...

Environmental compliance today, creating a sustainable tomorrow

Helping you reduce risk to the environment and your operation by managing assets compliantly while achieving commercial, ESG, and net-zero goals.

Contact our experts